What keeps your car’s camera from freezing in the winter or melting in the summer? What prevents critical components from corroding and failing when you need them most?

The answer isn’t luck. It’s materials engineering—the silent force behind the tools you rely on every day. As a materials engineer, I’ve worked to design coatings that withstand harsh environments, adhesives that endure vibration, and safety systems that save lives. Let’s explore how materials science quietly shapes the world you live in—and why it’s more essential than ever.

Why materials science matters: The backbone of modern innovation

Innovation often brings to mind electric cars that cut emissions, medical devices saving lives, or the smartphone that keeps us connected—but none of these exist without groundbreaking materials.

Yet, behind these innovations are materials designed to make the impossible a reality.

Think about your car’s camera failing because of harsh summer heat or icy winters. Materials science ensures that doesn’t happen.

This isn’t just about functionality; it’s about safety. According to McKinsey & Company, advanced safety systems, including ADAS, could reduce traffic fatalities by 15% by 2030. Every innovation in materials engineering contributes to that life-saving potential, which is why the work excites me so deeply.

Breaking boundaries in materials engineering

When I transitioned from dental materials to automotive safety, I discovered an unexpected truth: the principles I’d used to create stronger, longer-lasting dental implants could also enhance automotive components.

This adaptability highlights why materials science is so fascinating—a field where knowledge transfers seamlessly, often in ways you wouldn’t expect.

At ZF Global Electronics, I’ve had the privilege of working on some of the most exciting advancements in ADAS technology. One of the most impactful challenges I tackled was improving adhesive bonding in camera modules to handle both vibration and heat. After months of testing, we introduced a new heat-curing process that not only exceeded durability expectations but also streamlined production.

These aren’t just technical wins; they’re victories that ripple across industries, setting new standards for safety and reliability.

How materials engineers are solving tomorrow’s problems today

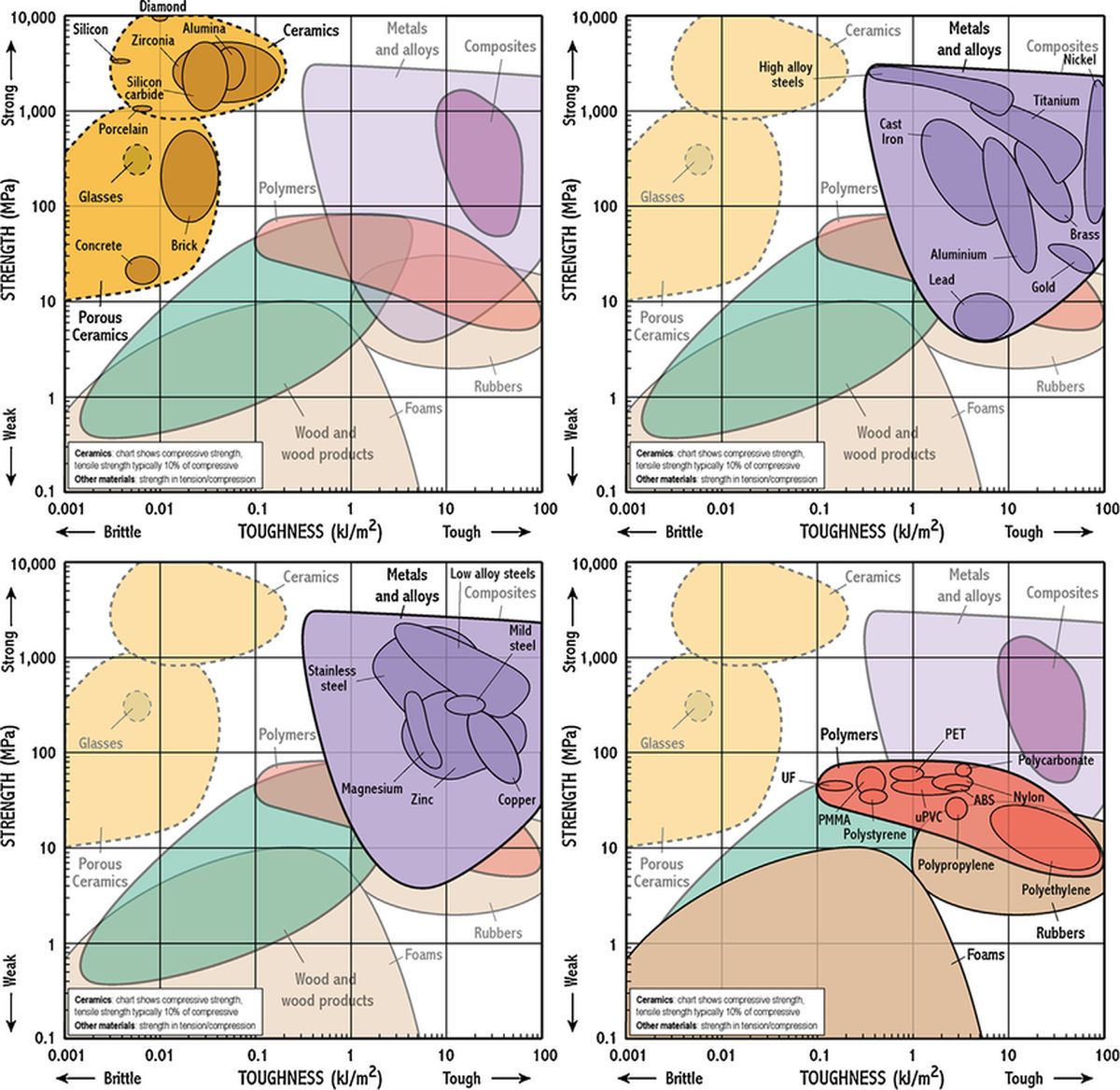

The world of materials engineering is evolving rapidly, driven by three major forces:

1. Electrification and autonomy

The rise of electric and autonomous vehicles demands lighter, stronger, and more efficient materials. Batteries must be energy-dense yet durable, while sensors and cameras must function flawlessly in all conditions. One of my current focuses is creating sustainable materials for these applications—solutions that combine performance with environmental responsibility.

2. Sustainability in practice

Steel, cement, and plastics—materials we use daily—contribute to 45% of greenhouse gas emissions globally, according to the World Economic Forum. Engineers like myself are working to develop materials that are not only more efficient but also more recyclable, reducing waste and energy consumption across industries.

3. Revolutionizing manufacturing

Technologies like 3D printing and nanotechnology are transforming how we think about materials. Imagine a world where components are printed to exact specifications, reducing waste and accelerating innovation. This isn’t science fiction; it’s happening now.

Behind the Scenes: How Materials Engineering Impacts Everyday Life

Materials science isn’t just about solving big-picture problems; it’s also about improving the everyday. Here are a few examples of how the field is shaping the world around us:

- Automotive Safety: Beyond ADAS systems, materials engineering has redefined airbags, seat belts, and crumple zones, making vehicles safer than ever.

- Medical Advances: From titanium implants to biocompatible coatings, materials science has revolutionized healthcare, improving patient outcomes and reducing recovery times.

- Consumer Electronics: The lightweight, durable materials in your smartphone are the result of years of research and innovation, ensuring devices are both functional and portable.

One of the most rewarding moments in my career came when a client’s feedback confirmed that our improved ADAS camera modules had already prevented potential accidents. Hearing that our work made a tangible difference reminded me why I chose this field—to turn challenges into solutions that save lives.

The role of collaboration in driving innovation

Great engineering thrives on teamwork—brainstorming with researchers, refining designs with manufacturers, and sharing findings in top journals.

During my time at Lear Corporation, I worked with a cross-functional team to implement advanced laser weld defect analysis. The project didn’t just save money annually; it raised safety standards for welded components, ensuring long-term reliability.

These collaborative efforts underscore an important truth: the best solutions often emerge when diverse perspectives come together.

The emotional connection: Creating a safer, smarter world

Materials engineering is about trust. People trust their car to protect them, their medical devices to work in critical moments, and their gadgets to perform without fail. My job is to make sure that trust is earned through reliability and precision.

Solving these invisible challenges—materials cracking under pressure or adhesives failing at the wrong time—is what drives true innovation.

What’s next: My vision for the future

My focus for the future is clear: create materials that support a greener planet, develop technologies that push boundaries, and help the next wave of engineers turn bold ideas into reality. Whether it’s designing sustainable solutions or mentoring the next generation, I’m committed to shaping the future of engineering in ways that matter.

The materials we create today won’t just shape technologies; they’ll redefine trust, protect lives, and build a more sustainable future for everyone.